Our Products

With more than 35 years of experience in producing cyclones and a fabrication capacity in excess of 150 units per year, HASON is the undisputed industry leader when it comes to supplying cyclones for process and industrial applications. We leverage this unrivalled expertise to build cyclones of all types:

- Reactor cyclones (carbon steel, C-1/2Mo alloy, 1-1/4 Cr – 1/2 Mo alloy)

- Regenerator cyclones (304H stainless steel)

- FCC cyclones – third stage separator systems

- External cyclones (ASME “U” certified and hydrostatic testing)

- Cyclones with a Stellite overlay

- Refractory lining

Our exclusive robotic welding technology helps improve efficiency and ensure consistency in the quality of our welds.

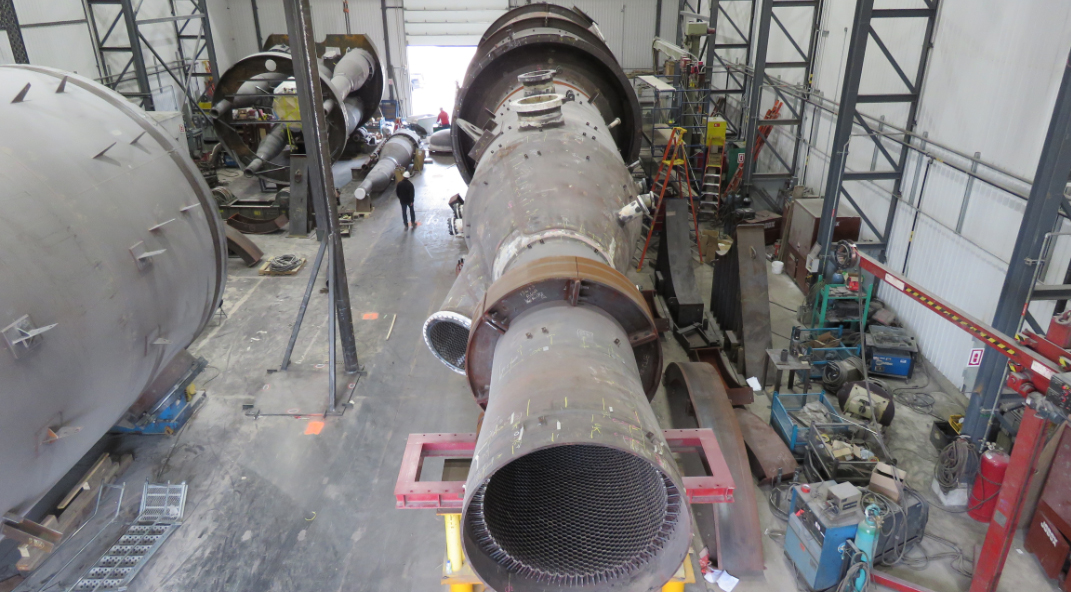

The benefits of HASON’s end-to-end fabrication of fully assembled pressure vessels and complex integrated components such as FCC reactors, regenerators and third stage separators are numerous.

- Maximized shop work for reduced turnaround field costs

- Reduced delivery lead times and less plant downtime as a result

- Improved production quality control for fabricated components

- Carbon steel and low temperature carbon steel

- Low alloys (Cr-Mo, C-Mo)

- Austenitic stainless steel (300 series)

- Ferritic stainless steels (400 series)

- Duplex steel

- Nickel alloys (Hastelloy, Inconel, etc.)

- Clad steel (explosion bond, rolled bond)

- Cyclones (Emtrol-Buell design)

- FCC internals and combustors (under UOP, Technip, KBR design)

- Air grids and plate grids

- Spent catalyst distributors, hoppers and wells

- Transfer lines (flue gas lines and reactor overhead lines)

- Steam rings and combustor rings

As a top specialist in refractory lining applications, HASON is uniquely positioned to cater to the needs of operators and stakeholders in the refinery industry, who understand the key role of this technology in maximizing FCC performance.

From preheat to DHT and PWHT, HASON is fully equipped to perform these operations – safely and reliably.

Plus, when it comes to welding, our critical joint approach and unique expertise developed over several decades allows us to ensure the quality and integrity of every last seam.