Réalisations - Complex FCC Assemblies

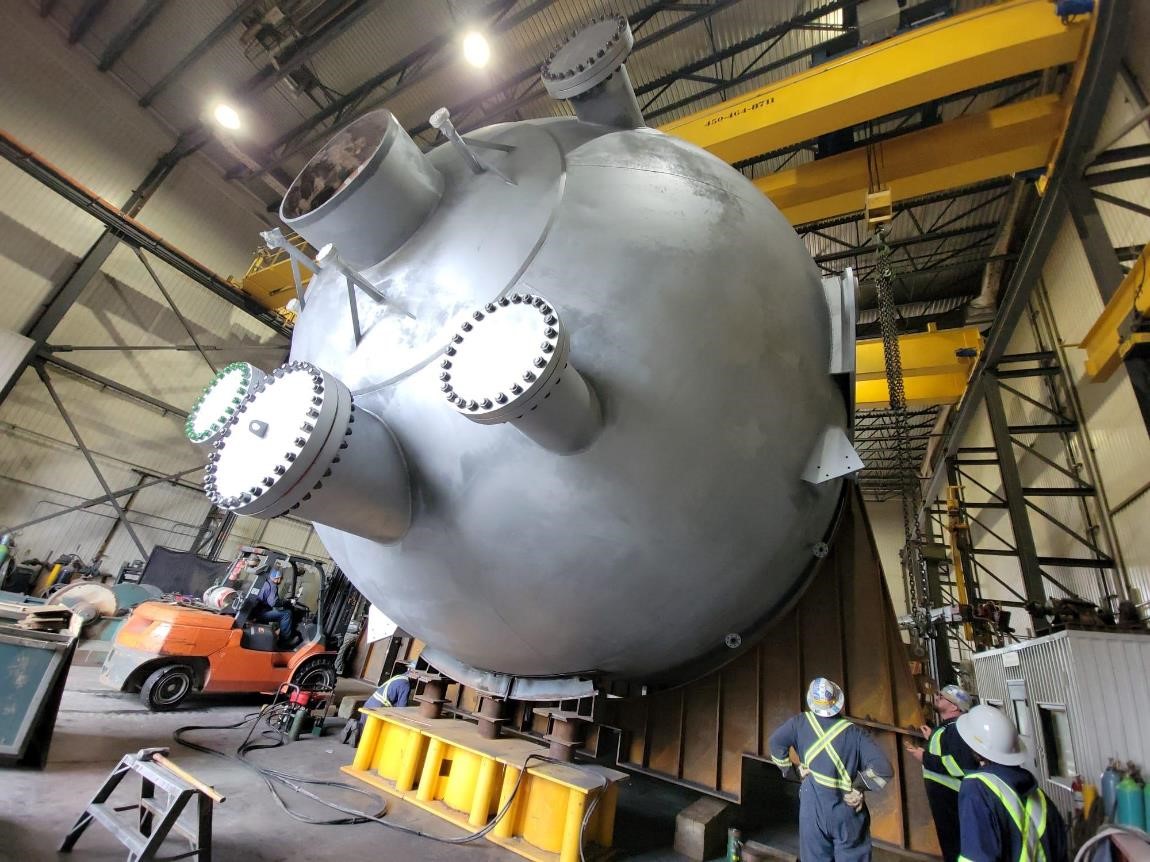

FCC reactor (cold wall)

FCC regenerator Assembled and hydrostatically tested for delivery in two sections by boat. Shipped with all internal components (Plenum, Cyclones, Airgrid, SCD) and refractory lining installed.

- Carbon steel

- 25′-0” diameter

- 840,000 lb.

- 98′-6” long

FCC Reactor (Hot wall)

- FCC reactor designed and fabricated per ASME Section 8 and API-934 including VSS internals, cyclone system, DHT, PWHT, external coating, refractory lining and full assembly for boat delivery as a complete unit.

- 1 ¼ Cr – ½ Mo (w/ API-934 restrictions)

- 17’-2” diameter

- 530 000 lbs

- 105’-0” long

FCC Reactor Stripper

- FCC Reactor stripper, completely assembled and hydrotested with support skirt, refractory lining, dryout and external coating.

- Carbon Steel

- 17’-6” diameter

- 167 000 lbs

- 42’-0” long

Tertiary Vessel

- Tertiary vessel upper section with cyclones installed and shipped as a single assembly.

- Carbon steel

- 15’-3” diameter

- 126 000 lbs

- 34’-0” long

Third Stage Separator

- FCC Third Stage Separator final assembly, refractory lining and barge delivery as a single piece.

- Carbon steel

- 17’-0” diameter

- 280 000 lbs

- 50’-0” long

FCC Reactor (Cold wall)

- FCC reactor assembled, hydrotested and knocked down in section for barge delivery.

- Stripper vessel was shipped fully welded with internals and refractory lining installed.

- Cyclones were shipped loose for field assembly.

- Carbon Steel

- 35’-0” diameter

- 1 800 000 lbs

- 120’-0” long